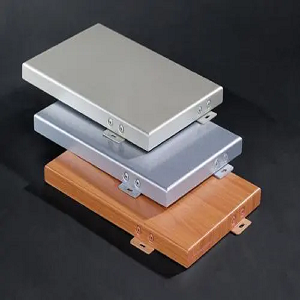

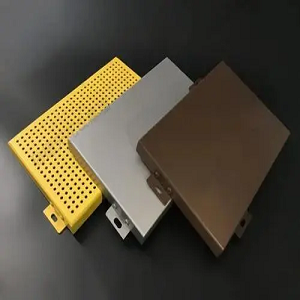

Decorative Building Exterior Wall Aluminum Veneer

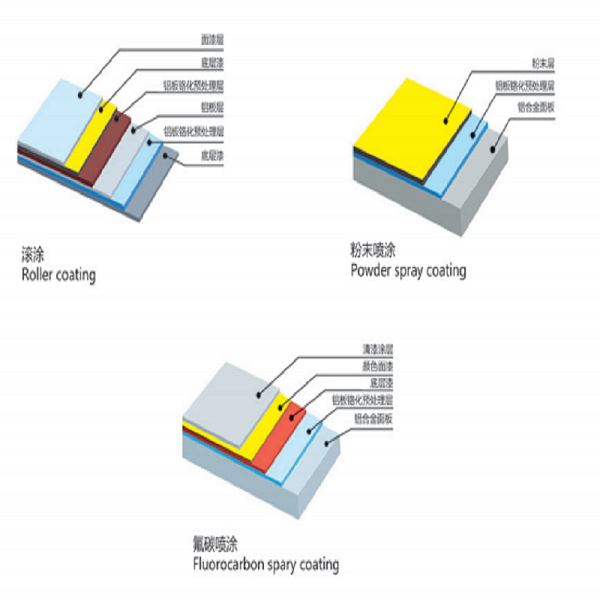

Aluminum veneer refers to a building decoration material that is processed by chromization and other treatments and then processed by fluorocarbon spraying technology. Fluorocarbon coatings mainly refer to polyvinylidene fluoride resin (KANAR500), which is divided into three types: primer, topcoat, and varnish.

The structure of aluminum veneer is mainly composed of panels, reinforcement ribs, corner brackets and other components. The maximum size of the formed workpiece can reach 8000mm×1800mm (L×W)

The coating is divided into two coatings and one baking, and three coatings and two baking. The coating performance meets the AAMA2605-98 standard of AAMA (American Building Manufacturers Association) and (ASCA American Building Spraying Association).

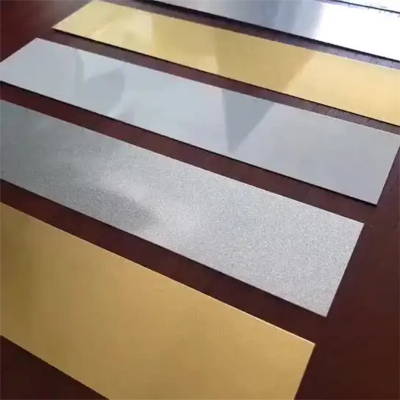

Conventional thickness: 1.5mm, 2.0mm, 2.5mm, 3.0mm.

Common specifications: 600*600mm, 600*1200mm

Product features

1. Light weight, good rigidity and high strength. 3.0mm thick aluminum plate weighs 8kg per square plate, with a tensile strength of 100-280n/mm2

Surface spraying process of aluminum veneer

2. Good durability and corrosion resistance. PVDF fluorocarbon paint based on Kynar-500 and Hylur500 can be used for 25 years without fading.

3. Good processability. Using the process of first processing and then painting, the aluminum plate can be processed into various complex geometric shapes such as planes, arcs and spheres.

4. Uniform coating and diverse colors. Advanced electrostatic spraying technology makes the adhesion between paint and aluminum plate uniform and consistent, with diverse colors and a wide range of choices.

5. Not easy to stain, easy to clean and maintain. The non-adhesiveness of the fluorine coating film makes it difficult for pollutants to adhere to the surface, and it has good cleanliness.

6. Convenient and quick installation and construction. The aluminum plate is formed in the factory, and no cutting is required at the construction site. It can be fixed on the frame.

7. Recyclable and environmentally friendly. Aluminum plates are 100% recyclable, and unlike glass, stone, ceramics, aluminum-plastic plates and other decorative materials, they have a high residual value.