5mm Closed Cell Aluminum Foam Sheet

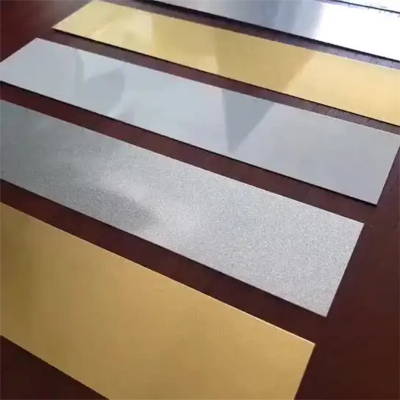

Features foam aluminum plate: foam aluminum bare plate retains the essence of is aluminum, silver gray metal appearance, Class A1 fire protection, corrosion resistance, aging resistance, smooth surface without hurting hands, natural and beautiful, uniform color, and suitable for large area building pavement engineering. The product has passed the test of the national testing agency, and meets the requirements of JG/T359-2012 foam Aluminum Plate for Building, which is safe, reliable and quality guaranteed.

Product description:

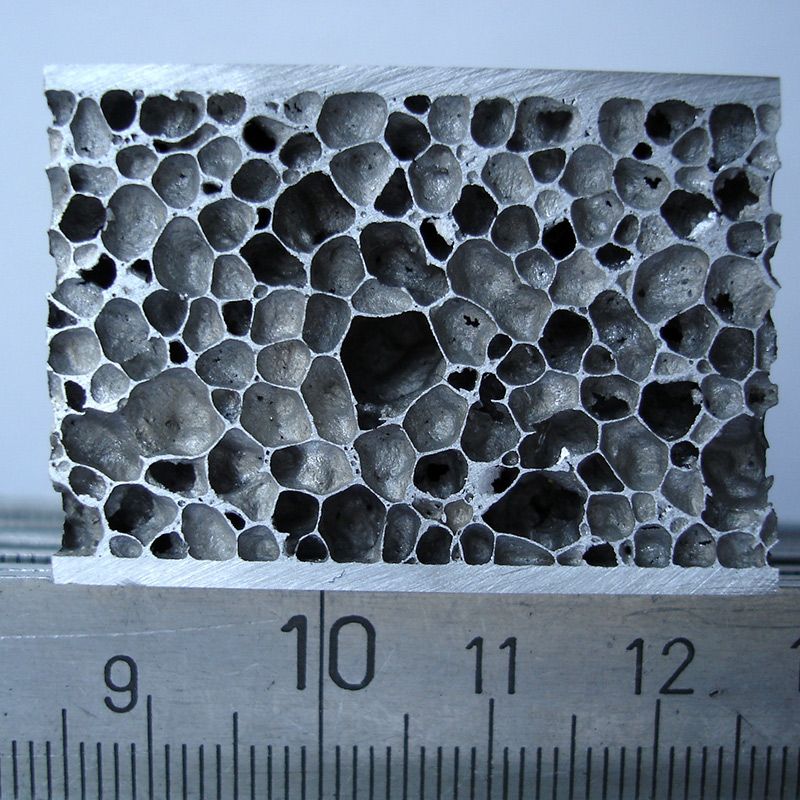

A 5mm closed cell blank aluminum foam plate with a size of 1 m × 2 m is an aluminum plate with a thickness of 5m and a size of 1 m wide × 2 m long. This type of aluminum sheet is characterized by a closed cell structure, which usually refers to the presence of small, evenly distributed closed holes or perforations on the surface of the sheet.

Foamed aluminum is a new kind of light metal material made of foamed aluminum alloy based on the principle of bionic structure. It is light, strong and less dense than water. It has many excellent properties such as sound insulation and noise reduction, electromagnetic shielding, energy absorption buffer, flame retardant and explosion prevention, and is widely used in transportation facilities, architectural decoration, military aerospace, civilian panel and equipment manufacturing.

Product parameters:

Inventory size :60cm*120cm can be customized to any size

Thickness :5mm ~ 10mm other customizable

Bright surface, silver gray aluminum essence, uniform aperture, A1 grade fire resistance, corrosion resistance, anti-aging, smooth surface, easy to clean, suitable for indoor and outdoor decoration

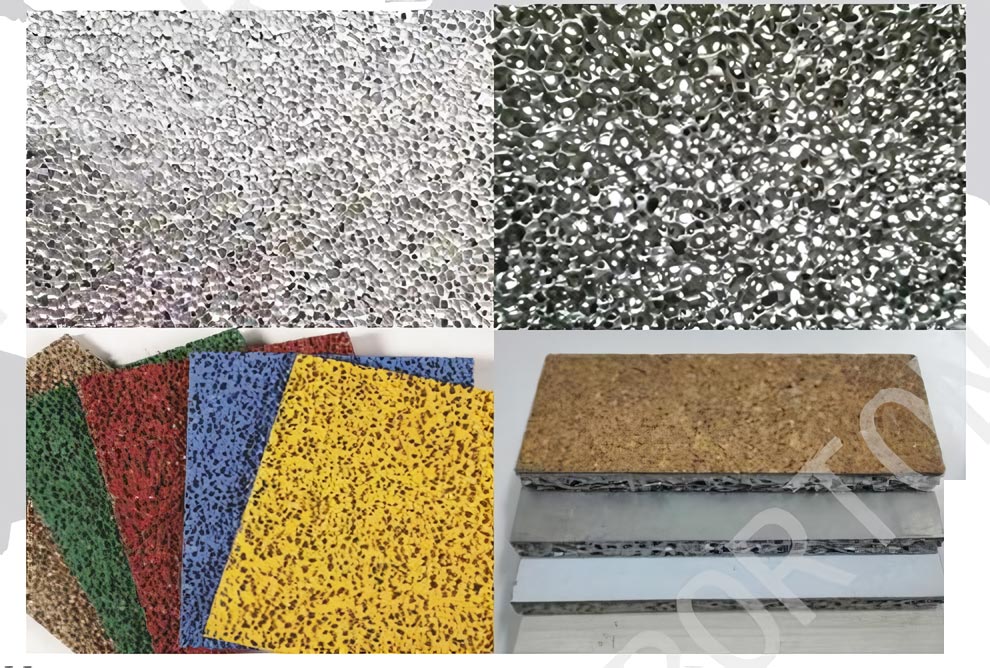

Product Classification:

1.Closed cell aluminum foam sheet

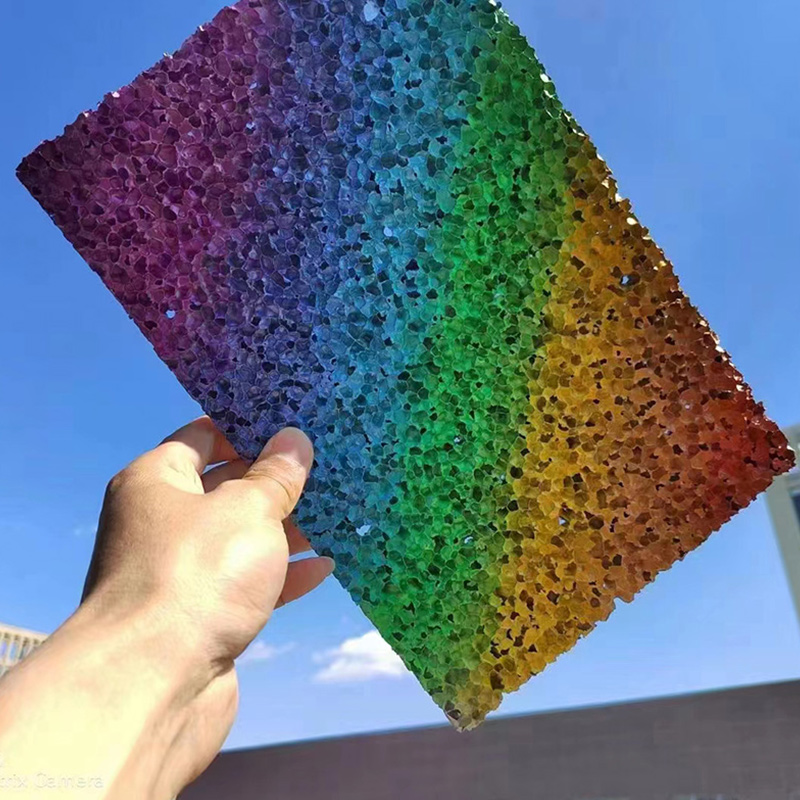

2.Through-hole aluminum foam Closed cell aluminum foam sheet plate (transparent plate)

3.Aluminum foam color plate

4.Aluminum foam composite board

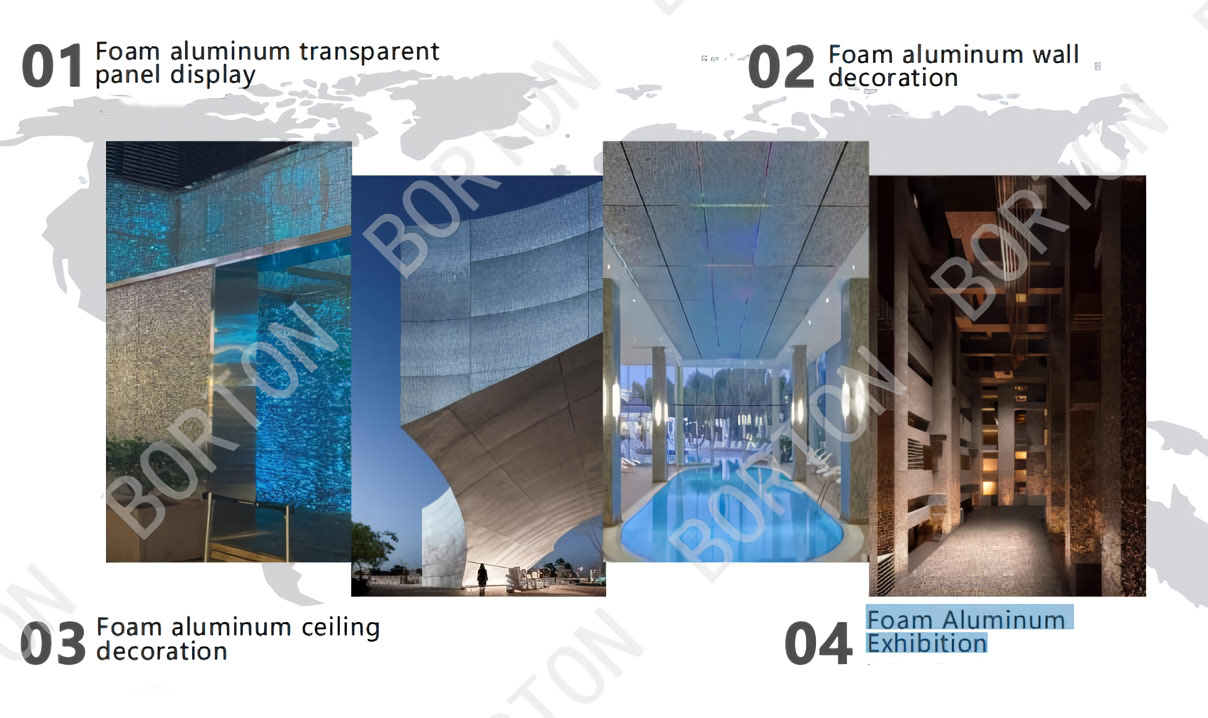

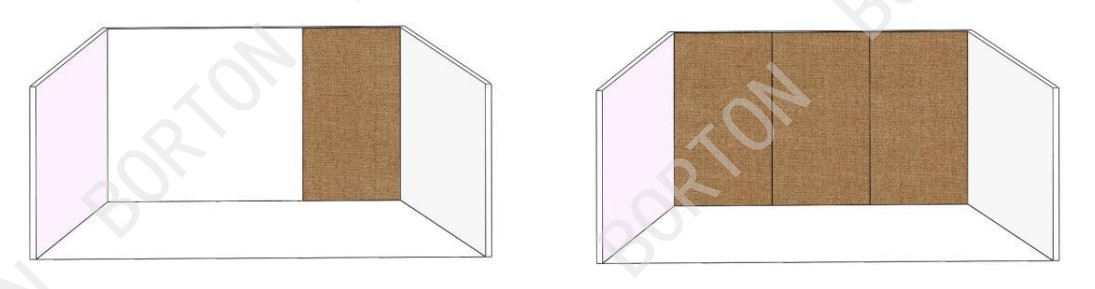

Decorative effect display:

Foam aluminum transparent panel display

Foam aluminum wall decoration

Foam aluminum ceiling decoration

Foam Aluminum Exhibition

Installation guidance plan:

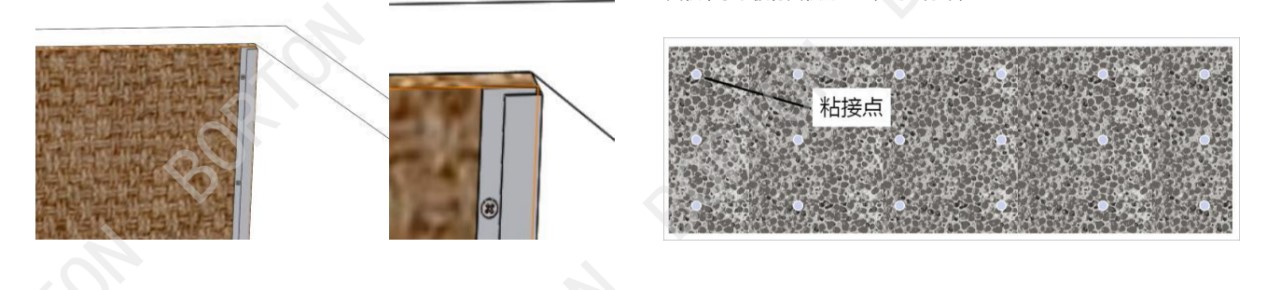

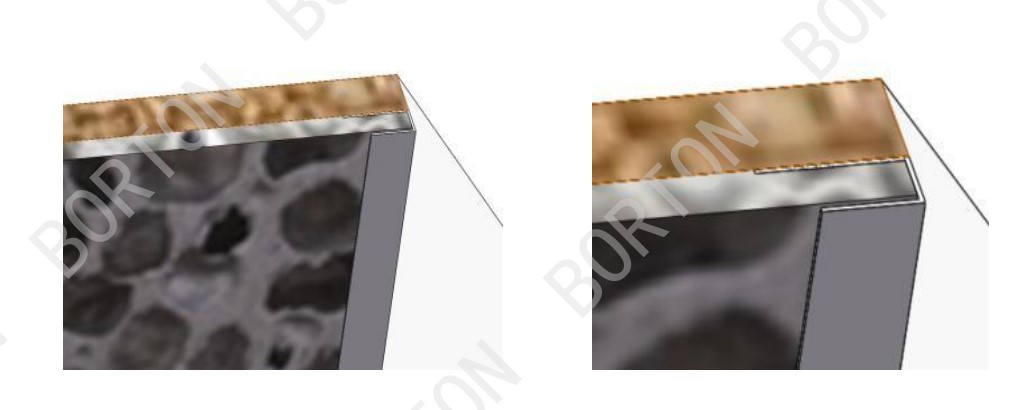

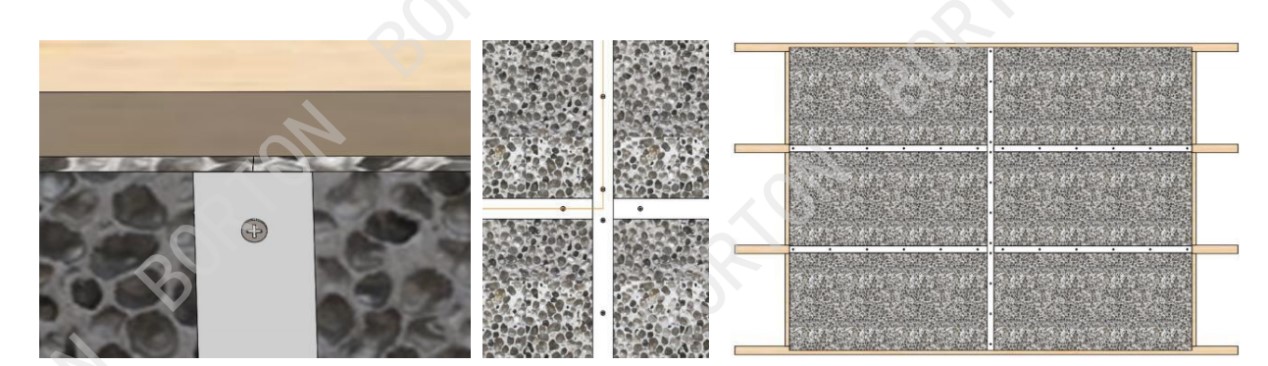

Scheme 1: Wall installation, fixed by card slot and adhesive

1. The wall is leveled to ensure that the wall is smooth, lay a layer of wood base on the wall, and fix it to the wall with a nail gun;

2.Set the wire, plan the installation position, and determine the size of the aluminum foam sheet;

3. Install the end interface card slot and fix it on the wooden base with screws

4. Apply adhesive on the back of aluminum foam sheet. The adhesive form can be spot adhesive or surface adhesive, and the adhesive area is not less

than 2% of the plate area, with uniform distribution;

5. Install the aluminum foam sheet in the predetermined position, and the edge is matched with the receiving slot;

6. Install the middle card slot, match with the other end of the aluminum foam sheet, and then fix it on the wood base with screws;

7. In accordance with the above method, fix the remaining plates on the wall in turn

Solution 2: Directly installed on the wall

When the wall is suitable for bonding, the aluminum foam sheet can be directly glued to the wall;

When the wall is not applicable and bonded, the aluminum foam sheet can be fixed on the wall with gun nails. The adjacent plates can be directly buttressed or gaps reserved for later use of T-shaped laminates to cover and fill.

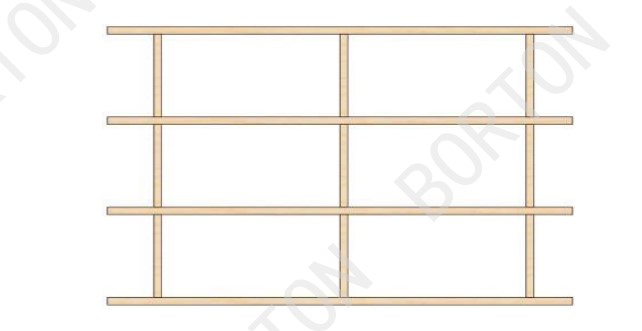

Scheme 3: Keel support installation of the aluminum foam sheet

1. Install the keel according to the size and installation direction of the aluminum foam sheet;

2. Lap between aluminum foam sheet and keel, and then use self-tapping nails or nail gun to connect and fix;

3. When the keel is narrow, it can also be fixed by layering.

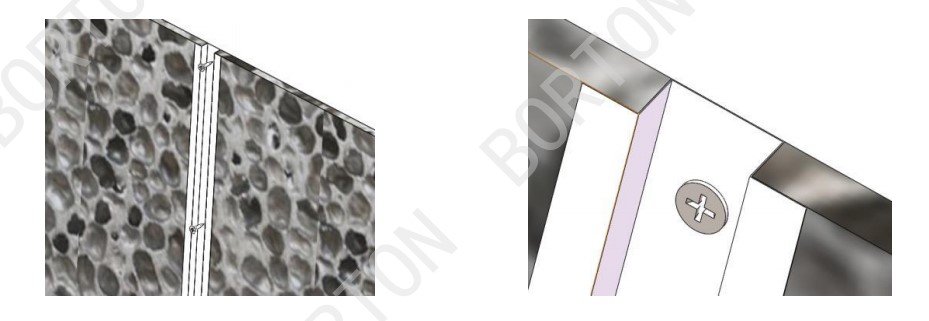

Scheme 4: The use of several types of slot fixed connection

The method is suitable for wall and ceiling keel installation.

1.Several strip sare placed in the installation gaps of adjacent aluminum foam sheets as

2.Support pieces between sheets,and then fixed to the wall or keel by screws. The

3.Connected grooves can be modified by decorative strips or lamp strips.

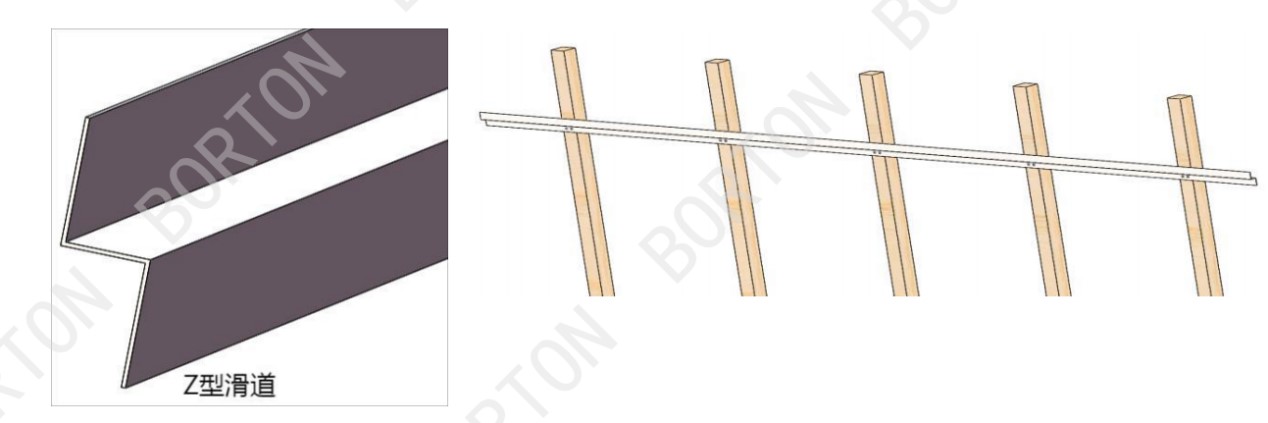

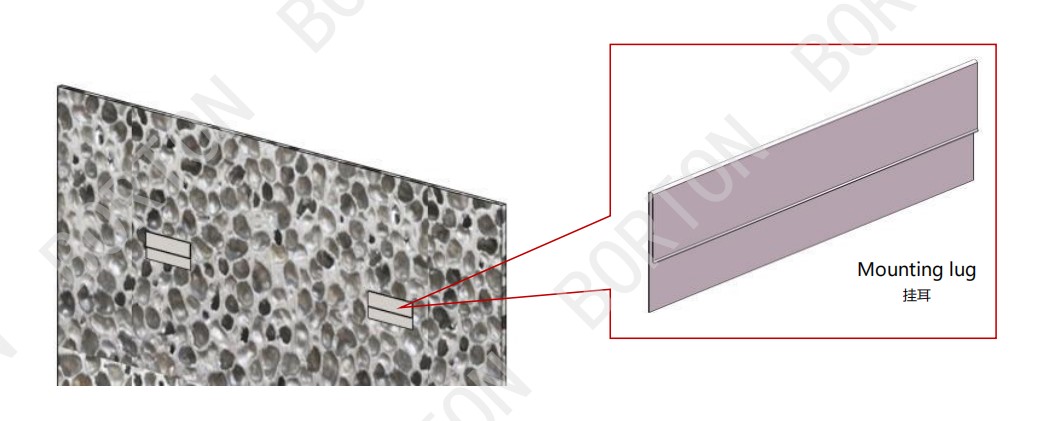

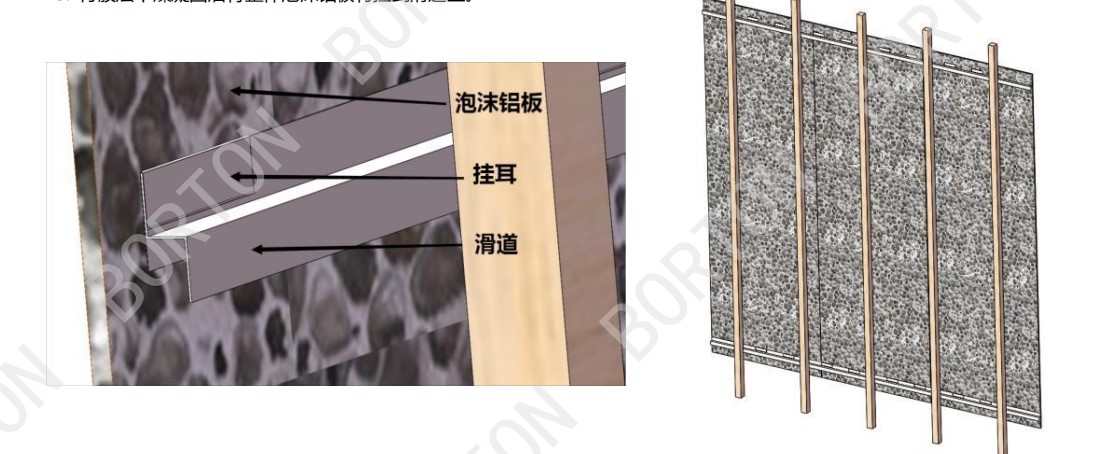

Solution 5: Hanging installation

1. First, install Z-shaped slide on the wall or keel for the fixed installation of aluminum foam plate;

2. Install mounting ears on the back of the aluminum foam plate. The mounting ears are U-shaped, and their wider sides are glued to the aluminum foam plate

3. After the rubber layer dries and solidifies, hang the aluminum foam sheet onto the guide rails.

Pakage:

Wooden box