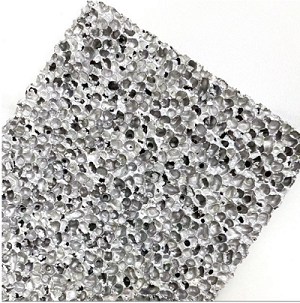

Close Cell Foam Aluminum Sheet For Sound Barrier

Foamed aluminum has excellent physical, chemical and mechanical properties as well as recyclability. These excellent properties of foamed aluminum give it a broad application prospect in today's material field. It is a promising engineering material, especially in the transportation industry, aerospace industry and building structure industry.

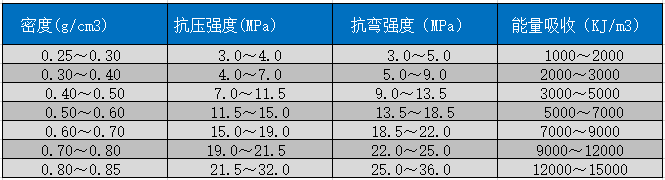

1. Lightweight: Density is 0.2-0.4g/cm3, which is 10% -40% of metal aluminum; Density is 0.2-0.4g/cm3, which is about 1/10 of aluminum density, 1/20 of titanium density and more than 1/30 of steel density;

2. Fireproof and heat-resistant: The thermal insulation effect of closed-cell foam aluminum is equivalent to that of marble, and it has high heat resistance. The melting temperature of general aluminum alloy is about 500-700 degrees, and foam aluminum does not dissolve even if heated to 1400 degrees;

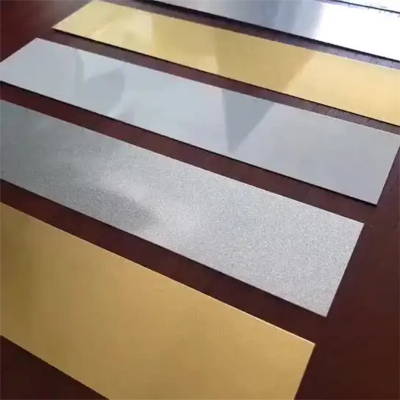

4. Ductility and plasticity: It is convenient to cut, drill and glue; it can be bent into the required shape by molding;

5. Non-combustible and heat-resistant: Good corrosion resistance and weather resistance, low moisture absorption, and no aging;

6. Easy to install: It can be connected and fixed by mechanical methods or directly with screws, or it can be pasted on the wall or ceiling with adhesive;

7. Electromagnetic shielding: Foam aluminum sheet is an excellent grade of electromagnetic shielding material, and its shielding efficiency reaches 200MHz or less for electromagnetic waves with radio frequency below 200MHz. 90dB. A 20mm thick iron plate with foam plastic can shield electromagnetic waves by 50dB. A single 20mm foam aluminum can shield electromagnetic waves by 90dB, and its weight is 1/50 of that of the iron plate;

8. Concealment performance: In a joint experiment with the Institute of Process Engineering of the Chinese Academy of Sciences, the foam aluminum material can play a concealing role after being sprayed with absorbing materials on the surface;

9. Automobile protection: However, its bending strength ratio can reach 1.5 times that of steel. Whether it is a Japanese low-strength longitudinal beam car or a European and American high-strength longitudinal beam car, it is necessary to solve the anti-collision problem. The foam aluminum anti-collision beam meets the requirements of absorbing the kinetic energy of the impact, causing a major change in the car body;

10. Shipbuilding industry: ordinary tugboats, cargo ships engine room noise reduction needs, engine room sound absorbing lining, partitions, hatches, high-performance decks, lightweight and high-strength ship structures, etc.;

11. Aerospace: The density of foam aluminum is only about 0.1 and 0.4 times that of metal aluminum. In the current aerospace field, honeycomb structure materials are widely used in the former aerospace field. Foam aluminum sandwich panels are similar to honeycomb structural materials, both of which are materials with low density and high specific strength. However, foam aluminum has a huge advantage in cost and may replace honeycomb structural materials in future development.